What Is the Industrial Internet?

As a brand-new industrial ecosystem, key infrastructure, and new application mode, the industrial Internet consists of three systems: the network, platform, and security systems. Through the full interconnection of all elements, including people, materials, and machines, the industrial Internet implements full connection of all elements, industry chains, and value chains. In addition, it accelerates the transformation and upgrade of traditional industries and the development of emerging industries.

What Is the Industrial Internet?

The industrial Internet is a new infrastructure, application mode, and industrial ecosystem that deeply integrates next-generation information communication technologies with the industrial economy. By fully connecting all elements, including people, machines, materials, and systems, the industrial Internet builds a brand-new manufacturing and service system covering the entire industry chain and value chain. It provides a way to realize the digital, networked, and intelligent development of industries, and is an important cornerstone of the fourth industrial revolution.

With the acceleration of digital transformation in numerous industries, enterprises have increasingly high requirements for efficient data asset flow. The industrial Internet plays an increasingly important role in the development of digital economy. It is necessary to build advanced industrial networks that lay a consolidated network system foundation in order to meet new requirements for connecting industrial devices, wireless network access, IP-based factory intranet, and intelligent factory extranet.

Why Do We Need to Develop the Industrial Internet?

With the development of technological and industrial transformation, the Internet has spread from the consumption field to the production field. Industries are also evolving from digitalization to networked and intelligent development, driving the birth of the Industrial Internet.

- Developing the industrial Internet to provide key support for the construction of a manufacturing power:

- Promoting traditional industrial transformation and upgrade

Through cross-device, cross-system, cross-factory, and cross-region interconnection, production and service resource configurations can be optimized more efficiently, more accurately, and across a broader scope. Such interconnection also helps improve quality and efficiency, reduce costs, and enable green and secure development. Furthermore, it transforms the manufacturing industry into a high-end, intelligent, and green one while also significantly improving the quality and benefits of industrial economic development.

- Accelerating the development of emerging industries

The industrial Internet promotes the evolution of industrial production from E2E digitalization to comprehensive integration, and accelerates the profound transformation of innovation modes, production modes, organization forms, and business paradigms. It also helps establish many new models, business forms, and industries, such as platform-based design, intelligent manufacturing, network-based collaboration, personalized customization, service-oriented extension, and digital management.

- Promoting traditional industrial transformation and upgrade

- Developing the industrial Internet to facilitate the construction of a cyber power:

- Accelerating network evolution and upgrade

The industrial Internet promotes the evolution from the public Internet and the Internet of Things (IoT), which respectively connect people and things, to the interconnection of all things, including people, machines, and systems. This significantly improves the support service capabilities of network facilities.

- Expanding the digital economy space

The industrial Internet can be deeply integrated with multiple industries to interconnect them in both upstream and downstream directions and across domains. Such integration also facilitates the scientific advancement of network applications, from virtual to physical and from life to production. This dramatically expands the development space of the digital economy.

- Accelerating network evolution and upgrade

To sum up, from the perspective of industrial economy and network infrastructure development, developing the industrial Internet has become the only way for industry development and an important measure for building a strong country.

What Does the Industrial Internet Include?

In April 2020, China's Alliance of Industrial Internet (AII) released Industrial Internet Architecture 2.0, proposing that the functional architecture of the Industrial Internet can consist of three systems: network, platform, and security. The network system is the basis, the platform system is the core, and the security system is the guarantee.

Network System

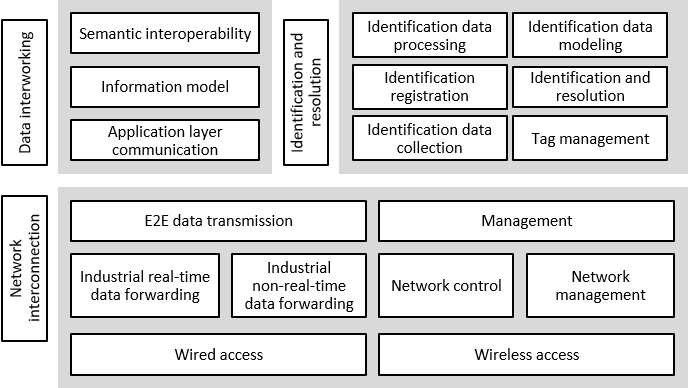

The network system of the industrial Internet includes three parts: network interconnection, data interworking, and identification and resolution.

- Network interconnection

Network interconnection refers to the connection between dumb facilities, dumb devices, and dumb terminals in wired or wireless mode to enable them to "speak". Through network interconnection, all elements — including people, machines, materials, laws, environment, upstream and downstream of enterprises, products, and users — are connected to implement data transmission between the elements.

Building an advanced industrial network featuring networked devices, IP-based connectivity, and network intelligentization supports ubiquitous connections of industrial resources, efficient data flow, and network security and drives the digital and intelligent transformation of industries.

- Data interworking

Data interworking enables seamless transmission of data and information between elements and between systems. In this way, heterogeneous systems can communicate with each other at the data layer, implementing data interoperability and information integration.

With the rapid application of AI and big data, industrial enterprises have increasingly strong requirements for data interworking. Standardization and "upstream and downstream delivery" have become the development trend of data interworking technologies.

- Identification and resolution

Such functions as identification data collection, tag management, identification registration, identification and resolution, data processing, and identification data modeling are provided to mark, manage, and locate elements. Identification and resolution implement unique positioning and information query for machines and items and are the prerequisite and basis for product lifecycle management, intelligent services, and precise interconnection between global supply chain systems and enterprise production systems.

With the in-depth implementation of the industrial Internet innovation and development strategy and the deepening of the industrial Internet's identification and resolution applications, identification and resolution-based data services become the core of industrial Internet applications. The closed-loop private identification and resolution system gradually evolves to an open one. The industrial Internet identification and resolution security mechanism has become the basis of industrial Internet applications, and it has become a consensus to develop secure and efficient identification and resolution services.

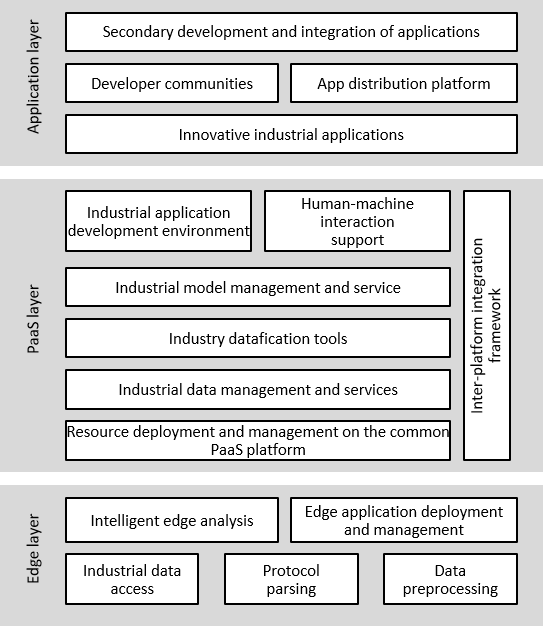

Platform System

To implement closed-loop data optimization and drive intelligent transformation of the manufacturing industry, the industrial Internet needs to provide a series of key capabilities, such as management of massive industrial data and various industrial models, industrial modeling analysis and intelligent decision-making, agile development and innovation of industrial applications, and industrial resource aggregation and configuration optimization. These functions, which are unavailable in traditional industrial digital applications, are the core of the industrial Internet platform.

The industrial Internet platform is equivalent to the "operating system" of the industrial Internet. It consists of three key functional parts: edge layer, PaaS layer, and application layer and is used for data aggregation, modeling analysis, knowledge reuse, and application innovation.

- Edge layer

- Provides access of massive industrial data, such as that of industrial devices including robots and machine tools and of information systems such as ERP, MES, and WMS.

- Provides protocol parsing and data preprocessing functions, unifies the format and implements semantic parsing of various multi-source heterogeneous data, deletes and compresses the data, and transmits the data to the cloud.

- Provides edge analysis application function to provide real-time analysis and feedback control for highly real-time application scenarios.

- PaaS layer

- Provides IT resource management functions through technologies such as PaaS, and integrates various frameworks such as edge-cloud synergy, big data, and artificial intelligence to support upper-layer service functions.

- Provides data management capabilities for massive industrial data and provides high-quality data sources for upper-layer modeling and analysis. Provides the model management function to classify, mark, and search for industrial models.

- Provides industrial modeling and analysis functions and integrates industrial mechanism modeling methods, such as application simulation analysis and service processes, and scientific data modeling methods, such as statistical analysis, big data, and artificial intelligence to implement in-depth mining and analysis of industrial data values.

- Application layer

- Provides innovative industrial application functions and builds various industrial app solutions to meet intelligent requirements such as R&D design, process optimization, energy consumption optimization, and operation management, helping enterprises improve quality, reduce costs, and improve efficiency.

- Provides the developer community function to build an open online community and provides various resource tools, technical documents, and learning and communication services to attract a large number of third-party developers to register with the platform for application innovation.

- Provides the app store function and services such as registration and qualification, display and distribution, and transaction charging for mature industrial apps to monetize their value.

- Provides secondary development and integration functions for existing industrial apps to adapt to specific industrial application scenarios and meet personalized requirements of users.

With the deepening of digital transformation in the manufacturing industry and the accelerated integration of next-generation information technologies, platform-based data intelligence has become the core driver of the intelligence in the entire manufacturing industry. The platform-based architecture has become a common choice for future digital systems, accelerating the convergence of industrial software and platforms. Platform-based application openness and innovation enable enterprises to quickly adapt to market changes and meet personalized requirements of users, and explore innovative business models and service forms.

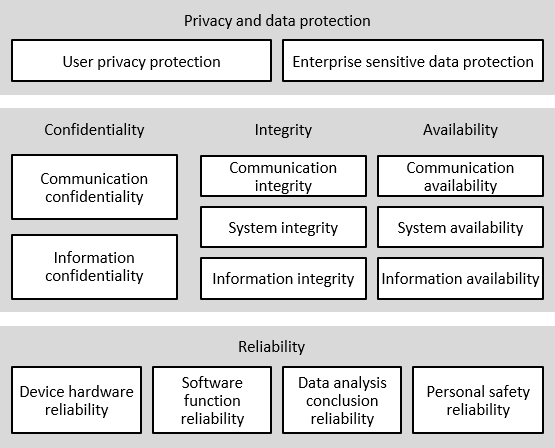

Security System

The industrial Internet security system involves network security issues in various aspects, such as devices, controls, networks, platforms, industrial apps, and data. In addition, those security issues involve a wide range and have great impact. In addition, the enterprise protection foundation is weak. To ensure the healthy and orderly development of the industrial Internet, the security system must feature reliability, confidentiality, integrity, availability, privacy, and data protection.

- Reliability refers to the capability or possibility of an industrial Internet service to perform a specified function without faults within a certain period of time and under certain conditions.

- Confidentiality refers to the feature that useful data and information in industrial Internet services are not disclosed to unauthorized individuals or enterprises as required.

- Integrity refers to the feature that industrial Internet users, processes, or hardware components can verify the accuracy of the sent information and that the processes or hardware components will not be changed in any way.

- Availability refers to the probability that industrial Internet services can run properly within a certain period of time or the expected time occupancy ratio. Availability measures the actual efficiency of industrial Internet services after they are put into use.

- Privacy and data protection refers to the capability of protecting personal privacy data of industrial Internet users or sensitive data owned by enterprises.

With the implementation of the industrial Internet in various industries, security will become an important cornerstone and protection center for the healthy and orderly development of the industrial Internet in the future. A multi-party collaborative defense system is built by establishing a comprehensive and flexible information sharing and collaborative handling mechanism. Information security and physical security are handled to ensure reliability, confidentiality, integrity, availability, privacy, and data protection in production management and promote the healthy and orderly development of the industrial Internet.

What Are the Typical Application Modes of the Industrial Internet?

The converged application of the industrial Internet promotes the emergence of a batch of new models and business forms, and have significant effect in improving quality and efficiency, reducing costs, and achieving green and secure development. Six typical application modes are preliminarily formed: platform-based design, intelligent manufacturing, network-based collaboration, personalized customization, service-oriented extension, and digital management.

- Platform-based design, based on the industrial Internet platform, aggregates design resources such as personnel, algorithms, models, and tasks to implement high-level and efficient lightweight design, parallel design, agile design, interaction design, and model-based design. Platform-based design transforms traditional design modes, and improves R&D quality and efficiency.

- Intelligent manufacturing is innovative application of next-generation information technologies, such as the Internet, big data, and artificial intelligence in the manufacturing field. It implements online connection and real-time interaction between production elements (such as materials, devices, and products) and users, and gradually replaces humans with machines in production. Intelligence represents the future development trend of the manufacturing industry.

- Network-based collaboration allows enterprises and partners in the supply chain to share various information resources such as customers, orders, design, production, and operation through cross-department, cross-level, and cross-enterprise data exchange and service interconnection. In this way, network-based collaborative design, production, and services will be realized, and resource sharing, capability transaction, and service configuration optimization are promoted. On the factory intranet, flattened, IP-based, wireless, and flexible networking are improved to implement fast data flow in the factory. On the factory extranet, services are quickly provisioned through the "IPv6 Enhanced" or "intelligent cloud-network". Intelligent O&M quickly streamlines communication with enterprise factories and branches and provides cloud-based services and product services.

- Personalized customization is oriented to consumers' personalized requirements. Through accurate acquisition and analysis of customer requirements, agile product development and design, flexible intelligent production, and precise delivery services, users can deeply participate in the entire product lifecycle. This manufacturing service mode realizes personalized product design, production, sales, and service with lower cost and higher quality and efficiency.

- Service-oriented extension is a new industry form that integrates manufacturing and services. It refers to the extension of enterprises from the original manufacturing services to high value-added services at both ends of the value chain, from mainly "processing and assembly" to "manufacturing+service", and from merely selling products to selling "product+service", including device health management, remote product O&M, device finance lease, shared manufacturing, and Internet finance.

- Digital management streamlines core data links to penetrate all production and manufacturing scenarios and the entire process. Based on extensive data aggregation, integration optimization, and value mining, business activities such as strategic decision-making, product R&D, production and manufacturing, operation management, and market services are optimized, innovated, and even reshaped, building a new data-driven efficient operation management mode.

What Are the Successful Applications of the Industrial Internet?

The Industrial Internet has been extended to 40 national economic categories, involving manufacturing fields such as raw materials, equipment, consumer goods, and electronics, as well as key industries such as mining, electric power, and construction, achieving wider and higher-level development. Now it has formed a variety of converged application practices.

Huawei has made many application practices to promote the innovation and development of the industrial Internet.

- Through network interconnection, all elements of the industry chain are connected.

On the factory intranet, the data center connects to the factory campus office or IT services to realize campus IoT through an all-IP network, and builds an engineering brain through big data analysis. On the factory extranet, the enterprise headquarters quickly provisions services through the "IPv6 Enhanced" or "intelligent cloud-network". Intelligent O&M quickly streamlines communication with enterprise factories and branches and provides cloud-based services and product services.

- Huawei helps a company build an intelligent industrial cloud network. The new IP backbone network meets service development requirements, and network slicing is used to isolate the operations of different production lines.

The backbone network uses industry-leading technologies, such as SRv6, FlexE network slicing, and SDN. The factory network uses the SDN architecture to build a 100G interconnection IP backbone network covering the entire company, meeting service development requirements in the next 5 to 10 years. This provides an ultra-broadband and flexible IP bearer platform for the group with accelerated industrial informatization development. This platform enables centralized control systems to go online quickly, to be cost-effectively, and to reduce investment for the group.

The IP backbone network of the group needs to carry both IT (office) and OT (production) services. The SLA requirements of different services vary greatly. Services of different production lines (such as cold-rolling, pre-ironmaking) and different joint-stock companies, are carried by different network slices.

- In a base, Huawei helps the customer build an advanced IT/OT converged network. The network uses all-wireless and IoT convergence technologies to connect more than 10,000 sensors, more than 2000 smart terminals, and more than 500 vehicles in process, implementing real-time collection of hundreds of millions of data records and second-level analysis and feedback. The unplanned downtime is reduced by 20%, the AGV application efficiency is improved by 40%, and the production efficiency is improved by 48%. The take time of one vehicle per minute is achieved, and the vehicle delivery time is shortened by 10%. Practice fully demonstrates that "connectivity is productivity."

- Huawei helps a mining customer build an IP network with deterministic service capabilities, eliminating information silos of multiple OT networks, and transforming the deployment mode of programmable logic controllers (PLCs) from distributed underground deployment to centralized deployment in the above-ground central control room. The number of downhole inspection personnel is reduced from more than 20 to more than a dozen, and the PLC fault recovery time is reduced from 2 hours to 30 minutes.

- Huawei helps a company build an intelligent industrial cloud network. The new IP backbone network meets service development requirements, and network slicing is used to isolate the operations of different production lines.

- Industrial Internet platform FusionPlant is built to support the digital transformation of industrial enterprises.

FusionPlant, an industrial Internet platform, provides digital transformation capabilities such as connection management, industrial applications, industrial big data, and industrial intelligence. Industry know-how solutions are developed through collaboration with partners to support digital transformation of industrial enterprises.

- An enterprise performs digital transformation and upgrade based on FusionPlant. The Huawei Cloud ROMA platform implements cross-cloud interconnection between cloud applications and offline data centers, quickly building efficient supply chain collaboration and online after-sales service solutions. In this way, procurement efficiency and supplier management level are improved, and customer satisfaction is improved through online services and service standardization.

- An enterprise deploys its next-generation S/4 HANA system on Huawei Cloud, on which effective interconnection is implemented between ERP and MES service systems, accelerating enterprise digital transformation and setting a benchmark for equipment manufacturing enterprises to transform toward the industrial Internet.

- An enterprise performs digital transformation based on the FusionPlant platform. Using Huawei Cloud, the enterprise quickly builds an online after-sales service solution to provide customers with remote O&M and online services, improving after-sales maintenance efficiency and reducing service costs. The cloud simulation system is launched to resolve product digital design verification issues, move product design quality verification forward, shorten the product trial production period, and quickly adapt to market requirements.

- An enterprise builds a big data project based on FusionPlant. The project is driven by data and focuses on valuable application scenarios. Through big data analysis and warning control, the project provides real-time enterprise insight, helps managers make effective decisions, and implements data-driven management transformation.

- AIFW protects the production network and builds the best security practice solution for AII.

A world-leading integrated circuit wafer foundry enterprise does not have its production network divided into proper areas. Once malware penetrates into the network, worms spread quickly on the intranet, threatening the entire production network. In addition, unknown malware is difficult to identify, and network security risks exist. The enterprise deploys the intelligent detection engine of Huawei AIFW, which implements 4–7 levels of security protection for important devices that are open to vulnerabilities. Huawei HiSec solution is implemented to build the best security practice solution for China's industrial Internet industry.

- Author: Liu Yanyan

- Updated on: 2023-08-02

- Views: 1885

- Average rating: