What Is an Intelligent Wind Power Network?

Traditional wind farms currently rely on on-site O&M and inspections, which fall short of the requirements for large-scale wind farm construction. Digital and automated technologies are urgently needed to improve O&M and inspection efficiency and enhance security and quality control. The intelligent wind power network offers a systematic network solution that facilitates security control of wind power O&M and inspections, resulting in reduced costs and improved efficiency.

Why Do We Need an Intelligent Wind Power Network

Wind power generation involves converting wind energy into mechanical energy, which is then transformed into electrical energy. In a wind farm, numerous large wind turbines are installed at a location where there is ample wind resources, forming a cluster that supplies power to the grid. A wind farm typically comprises the wind turbine generator system, transmission lines, booster station, and centralized control center. The wind turbine generator system converts wind energy into electrical energy, which is then sent through the transmission lines to the wind booster station. The booster station amplifies the electrical energy before sending it to the power grid. Overseeing the operation of the entire wind farm is the centralized control center, which remotely monitors all wind turbine generator systems.

In recent years, there has been a global focus and consensus on the development of clean and green energy. Wind power, as one of the most important sources of clean energy, plays a major role in the energy structure of many countries. For example, China committed itself to the "double carbon" goal in 2020, aiming to achieve "peak carbon" emission by 2030 and become "carbon neutral" by 2060. To accomplish this goal, the country needs to optimize its energy structure and actively promote the development of clean energy. There has been rapid development of wind power in China over the past few years, driving a continuous increase in the accumulated scale of wind turbine installations in the wind power industry.

To ensure power is generated at optimal efficiency, wind farms require periodic checks of power generation and transformation equipment, monitoring of indicators, and prompt detection of exceptions in order to prevent equipment faults. However, the expansion of wind power generation means that the traditional on-site O&M and inspection mode — as well as the network infrastructure — are no longer able to meet the requirements of large-scale wind farm construction, posing a number of challenges to such construction.

Challenge 1: Difficult to Ensure Personnel Security

Wind farms are typically situated in remote areas with limited network coverage. This makes it difficult for inspection personnel to communicate with each other in real-time while inspecting the wind turbines. After leaving the booster station, the personnel risk losing connectivity. Furthermore, the metallic structure of the wind turbine obstructs communication with the outside world. This presents a significant challenge in the event of high-risk incidents such as falling objects or electric shocks, because external parties may not be able to respond promptly. As such, wind power enterprises must adopt a range of intelligent measures to ensure reliable communication and implement robust security controls.

Challenge 2: Low Inspection and O&M Efficiency

In a large wind farm, a team of two to five inspectors typically needs to inspect numerous wind turbines spread across a 200 km radius on a monthly basis. However, it takes approximately two hours to inspect each wind turbine. If an issue is discovered, because of the limited network coverage at the wind turbine area, the inspection team must return to the centralized control center to issue two tickets — a work ticket and safety permit, commonly used in wind farms — and wait for approval. Consequently, the inspection efficiency is low. The work ticket is a means of controlling unconventional operations, whereas the safety permit is a means of controlling major sources of danger. During inspection, the personnel also need to manually enter inspection data, involving a heavy workload. They lack a mobile and intelligent inspection platform.

Challenge 3: High Turnover of Employees

Due to the challenging working conditions, it can be difficult for skilled technical personnel to maintain their positions for extended periods of time. This leads to a high turnover rate and poses significant challenges to the stability of the inspection team. In the future, wind farms are likely to become more automated and less reliant on human labor, replacing manual operations with robots and video surveillance. Implementing these digital inspection methods requires a high-bandwidth, highly reliable network that is easy to manage and maintain.

Overall Architecture of the Intelligent Wind Power Network

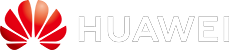

The intelligent wind power network provides end-to-end network connections from the wind turbine area and wind farm booster station to the regional centralized control center.

Basic architecture of Huawei's intelligent wind power network

Wind Turbine Area

Deploying Wi-Fi 6 APs in the wind turbine area enables complete wireless coverage both inside and around the wind turbines, delivering high-quality access for wind turbine sensors and inspection terminals. Two separate industrial switch networks are utilized to isolate production control services from production management services, ensuring the reliability of the production system.

- The wind turbine Wi-Fi network covers the interior and surrounding areas of each wind turbine, allowing wireless access for inspection recorders, handheld smart terminals, and smart safety helmets used by O&M and inspection personnel in the wind farm. This enables the personnel to issue two tickets on-site, with real-time access and backhaul of remote video, voice, inspection video and images, and other data.

- The backhaul network, adopting a ring topology composed of switches, connects the wind turbine area to the booster station, and sends various types of data in this area back to the booster station for management and analysis. This topology provides low-latency link switchover protection, ensuring data backhaul reliability.

Wind Farm Booster Station

- The wired network within the booster station connects downstream to wired terminals such as PCs, APs, printers, and cameras. In the upstream direction, it connects to the regional centralized control center through the WAN. The wired network facilitates the horizontal forwarding of intra-station traffic, and vertically aggregates and forwards traffic between terminals and the regional centralized control center.

- The wireless network in the booster station provides access to various wireless terminals in indoor and outdoor areas. Indoor terminals include office PCs and mobile phones. Outdoor terminals include inspection robots, handheld inspection terminals, mobile phones, and smart safety helmets.

Routers are deployed at the booster station and regional centralized control center to provide intelligent scheduling for services such as inspection data, office work, and remote expert support, ensuring service experience and reducing network leasing costs.

Regional Centralized Control Center

- In the regional centralized control center, a network management and control platform is deployed to implement unified management and end-to-end visualized O&M of all network devices, improving O&M efficiency.

- A security analysis platform is deployed to collect security threat event information — such as network traffic, security logs, vulnerability scanning logs, and host security data — for unified and comprehensive analysis. The information is then analyzed in a unified and comprehensive manner to improve the accuracy of security analysis and enable precise source tracing. If a violation is detected, the subject is immediately blocked and integrated collaborative protection is implemented to establish an end-to-end defense system for the wind power network.

What Are the Advantages of the Intelligent Wind Power Network

The intelligent wind power network has the following advantages:

High-Quality Wi-Fi Network

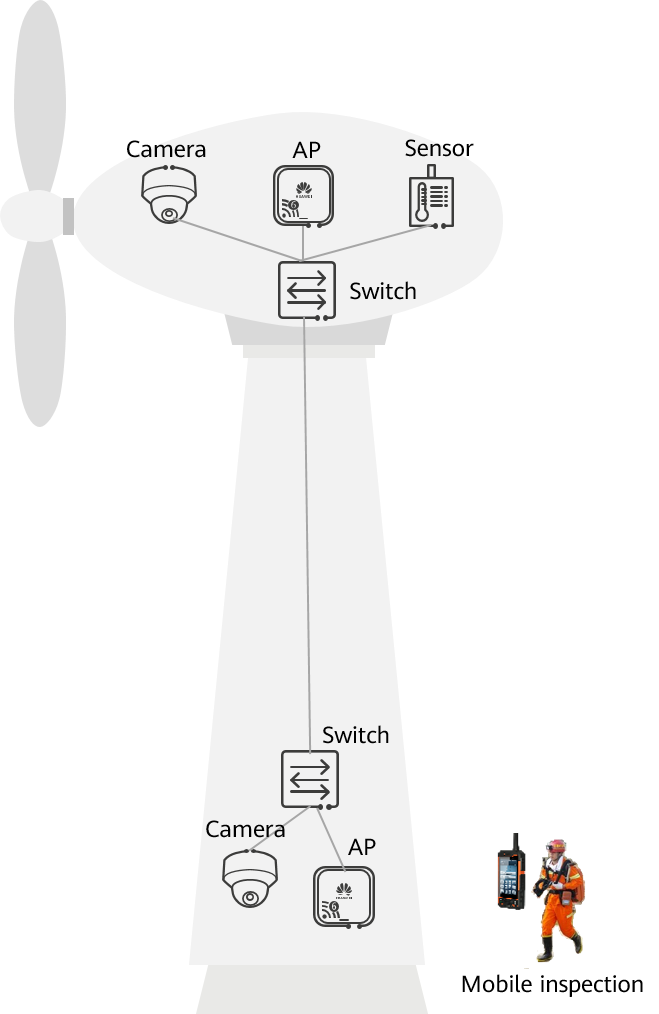

As shown in the following figure, a Wi-Fi 6 AP is deployed in the wind turbine nacelle and tower to implement wireless coverage both inside and around the turbine. Furthermore, the tower AP can extend coverage to nearby roads through Wi-Fi mesh, enabling seamless network access for mobile operations and remote expert support. This facilitates real-time data backhaul, significantly enhancing O&M efficiency and operational security.

Wi-Fi network for the wind turbine area

Intelligent Application Acceleration

In scenarios such as remote expert support and emergency command during wind farm inspections, stable and smooth audio and video communication is crucial to ensuring accurate and efficient operations. The intelligent wind power network utilizes SD-WAN intelligent scheduling to identify key applications and deliver high-priority SLA assurance. This ensures that no artifacts occur during video playback and that no interruption occurs during audio playback, guaranteeing a seamless experience.

Integrated Security Capability

Due to the many sensors and smart terminals connected to wind farms, security management is a challenging task. To address this, a security analysis platform is deployed on the intelligent wind power network in order to detect and quickly block potential threats such as cyber attacks and terminal spoofing, ensuring optimal network security.

Unified Cloud Management Capability

There are numerous network devices within wind farms. The intelligent wind power network uses a network management and control platform to centrally manage APs, routers, and switches. It monitors and visually presents network quality in real time, providing O&M personnel with the information needed to quickly identify and rectify faults.

- Author: Qiu Mingyan

- Updated on: 2024-04-09

- Views: 82

- Average rating: