What Is PLC-IoT?

Power Line Communication Internet of Thing (PLC-IoT) is an HPLC/IEEE 1901.1-compliant mid-band Power Line Communication (PLC) technology launched for industrial IoT scenarios to transmit data over power lines on low-voltage networks. PLC-IoT eliminates the need to roll out additional communication lines and delivers reliable, secure, and efficient communication in the "last mile" of IoT.

Why Do We Need PLC-IoT?

IoT Communication Technology

Continued breakthroughs in communication technologies drive the rapid development of IoT. People have increasingly fast-growing requirements on data collection for IoT terminals. To achieve connectivity of everything and ensure reliable, secure, and efficient communication in the "last mile" of IoT, various IoT access technologies are urgently needed.

IoT communication technologies fall into two categories: wireless communication technologies (for example, Bluetooth, Wi-Fi, and ZigBee) and wired communication technologies (for example, industrial field bus and PLC). PLC reuses power lines to transmit data, enabling connections to IoT devices without the need to deploy dedicated lines. It does not have the problem of severe impact from surrounding environments (such as poor signals) encountered by wireless communication technologies or problems of severe impact from line characteristics and poor openness and interoperability encountered by industrial field bus technologies.

PLC resolves the impossibility of sharing the same network by different communication technologies and eliminates the need of extra investments. By transmitting data over power lines, connectivity of everything will not be far from reality.

Depending on the frequency band and transmission rate, PLC is further divided into narrowband PLC, mid-band PLC, and broadband PLC, as listed in the figure below.

Category |

Frequency |

International Standards |

Technical Highlights |

Application Scenario |

|---|---|---|---|---|

Narrowband PLC |

< 148.5 kHz (EU) < 4920 kHz (FCC) |

IEEE P1901.2 |

Low rate and massive connections: Rate: < 150 kbit/s Latency: > 200 ms in most cases Number of connections: up to 1000 Transmission distance: > 1 km |

Low-speed connection scenarios: medium- and low-voltage power distribution network automation, meter reading, etc. |

Mid-band PLC |

0.7 to 12 MHz |

IEEE 1901.1 |

Low latency and high reliability: Rate: 150 kbit/s to 10 Mbit/s Latency: < 50 ms Reliability: 99.999% |

IoT scenarios with high reliability and real-time control: smart meters, smart traffic lights, single-lamp control, etc. |

Broadband PLC |

1.8 to 30 MHz 1.8 to 100 MHz |

IEEE 1901 ITU-T G.hn |

Large bandwidth: Rate: 200 Mbit/s to 1.5 Gbit/s Latency: < 50 ms Transmission distance: < 200 m |

Home broadband access and interconnection |

Emergence of PLC-IoT

PLC-IoT is an innovative practice of applying PLC in IoT scenarios. Based on HPLC/IEEE 1901.1, PLC-IoT is a mid-band PLC technology oriented to IoT scenarios. It resolves problems such as signal attenuation and interference on power lines. In the meantime, it implements IP-based communication.

- PLC-IoT operates in the frequency band ranging from 0.7 MHz to 12 MHz, featuring low and stable noise and good channel quality.

- PLC-IoT uses the orthogonal frequency division multiplexing (OFDM) technology, which has high frequency band utilization and strong anti-interference capability. By modulating digital signals in high-frequency carriers, PLC-IoT transmits data at a high speed across a long distance over power lines.

- PLC-IoT delivers an application-layer communication rate in the range from 100 kbit/s to 2 Mbit/s and can extend the transmission distance to several kilometers through multi-level networking. With IPv6, abundant IoT protocols can run over power lines, enabling intelligent end devices and implementing full connection of devices.

PLC-IoT establishes an accurate power line communication channel transmission model and determines the optimal signal transmission frequency based on the physical characteristics of power lines. Based on a large amount of measured data, PLC-IoT determines the channel characteristics of power lines, including the attenuation, impedance, and noise characteristics of signals. Based on these characteristics, PLC-IoT effectively mitigates noise and attenuation, significantly improving the communication performance of power lines and achieving high-speed, reliable, and real-time long-distance communication.

How Does PLC-IoT Work?

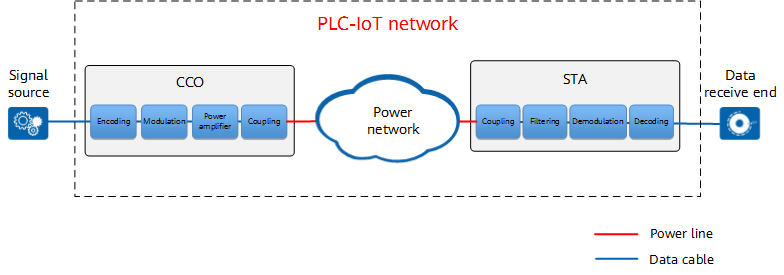

The implementation of PLC-IoT is simple and is described as follows:

- At the signal source side, the PLC modulation module modulates the data signals to be transmitted into high-frequency signals through a series of operations such as encoding and modulation, and couples the high-frequency signals to power lines through coupling circuits.

- At the receive end, the PLC demodulation module separates data signals from high-frequency signals transmitted over power lines, and performs demodulation to restore the original data signals.

To put it simply, the PLC module modulates the communication data sent by the signal source into high-frequency electromagnetic waves and transmits them to the data receive end over power lines. The PLC module at the receive end then separates the high-frequency electromagnetic waves from the current.

PLC-IoT network

PLC-IoT Communication Model

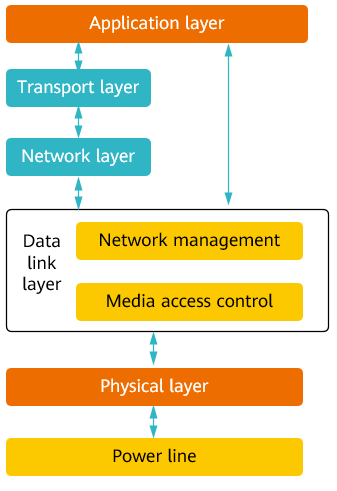

To understand how PLC-IoT works, let's first look at the communication model of traditional PLC and the improvement PLC-IoT makes on it.

The traditional PLC communication model consists of the physical layer, data link layer, and application layer. The data link layer directly transmits service data to the application layer. Based on the Open Systems Interconnection (OSI) model, the network layer and transport layer are incorporated into the PLC-IoT network architecture. The IPv6-capable network layer implements standard IP network communication through TCP/IP. This allows applications to run on the network layer (IP layer), instead of the data link layer.

PLC-IoT communication model

- Physical layer

PLC-IoT communication signals are transmitted over power lines. The physical layer encodes and modulates data packets that need to be transmitted by the data link layer into carrier signals and sends the carrier signals to power lines. In addition, the physical layer receives carrier signals transmitted over power lines, demodulates and decodes the signals, and sends the signals to the data link layer for transmission.

- Data link layer

This layer is responsible for network management and media access control.

- Network management: implements PLC-IoT network establishment, maintenance, and route management, and aggregates and distributes network-layer packets.

- Media access control: ensures reliable transmission of all data packets.

- Network layer

IoT scenarios involve a huge number of terminals and require efficient transmission of lightweight IP packets. The network layer of PLC-IoT supports the lightweight IPv6 protocol — IPv6 over Low power Wireless Personal Area Networks (6LoWPAN) — to implement IPv6-based communication on the PLC-IoT network.

- Transport layer

This layer provides reliable end-to-end network data flow services for the upper layer.

- Application layer

This layer exchanges service data between PLC communication units. Additionally, PLC-IoT uses Datagram Transport Layer Security (DTLS) and Constrained Application Protocol (CoAP) to ensure secure and reliable data transmission over power lines.

PLC-IoT Networking

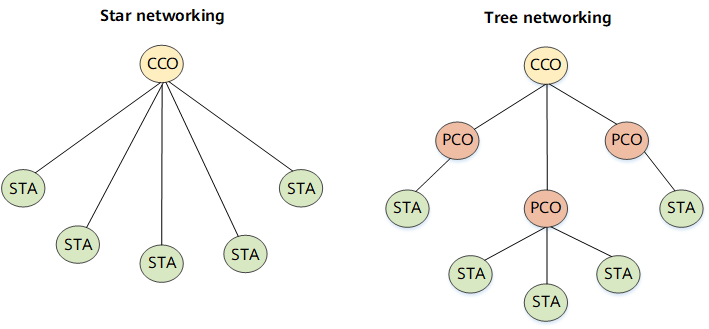

Depending on the cabling environment and terminal connection mode in actual industry application scenarios, the PLC-IoT network can use a star or tree topology, as shown in the following figure. The tree topology supports up to 8-level networking, which further extends the carrier transmission distance.

PLC-IoT networking

The PLC-IoT network supports the following roles:

- Central Coordinator (CCO): The CCO is responsible for the access of end devices as well as the receiving and sending of data.

- Proxy Coordinator (PCO): The PCO is supported only in tree networking and is a site that relays and forwards data between the CCO and sites or between sites.

- Station (STA): The STA receives and sends PLC signals and provides terminals with unified access to the PLC-IoT network.

The PLC-IoT network has the following features, which help achieve fast networking:

- Fast level-by-level convergence and proxy authentication, enabling a large number of sites to quickly connect to the network.

- Fast path evaluation and optimal path selection, improving the STA communication success rate after network access.

- Dynamic timeslot management and self-adaption upon multi-phase imbalance in transformer districts, maximizing bandwidth utilization.

- Up to 512 nodes supported by a single gateway and up to 8-level networking, extending the coverage of transformer districts.

PLC-IoT Network Establishment

The following uses the tree topology as an example to describe the PLC-IoT network establishment process:

- After devices are powered on, the CCO performs PLC detection on the entire network and determines the nodes that function as the PCO and STA based on the PLC parameters and communication parameters of network nodes.

- The CCO intercepts request packets of the STA or proactively sends requests to the STA, and implements transmission management and control by using a carrier detection technology.

- After being powered on, a STA sends a network access request to the PCO or CCO, based on the PLC-IoT network status. After receiving the access request, the PCO authenticates the STA and sends a network access request to the CCO. After the CCO receives the network access request, the STA can access the PLC network, achieving data communication.

Industry Application of PLC-IoT

PLC-IoT enables high-speed, reliable IoT communication over power lines, with almost no major roadworks, reducing the communication construction and deployment costs by over 50% and greatly shortening the deployment period. As such, PLC-IoT is ideal for a broad range of IoT scenarios, such as smart traffic lights and smart street lamps.

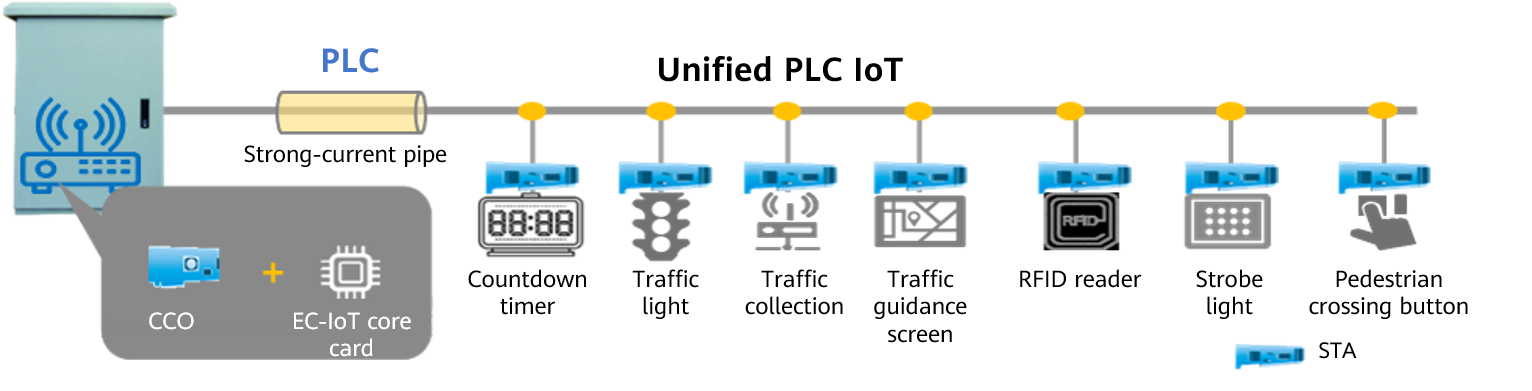

Smart Traffic Lights

Powered by PLC-IoT, the smart traffic light solution transmits data over legacy power lines. By reusing legacy facilities and adding PLC-IoT-capable devices, this solution implements centralized management of traffic control devices, such as traffic lights, countdown timers, and traffic guidance screens. In addition, this solution leverages edge computing technologies to break information silos between systems and exchange and share intersection data, implementing intelligent linkage with traffic conditions, for example, intelligent detection of signal light faults and online query of signal light information. This solution builds smart intersections and enables transformation towards intelligent traffic management.

Smart traffic lights

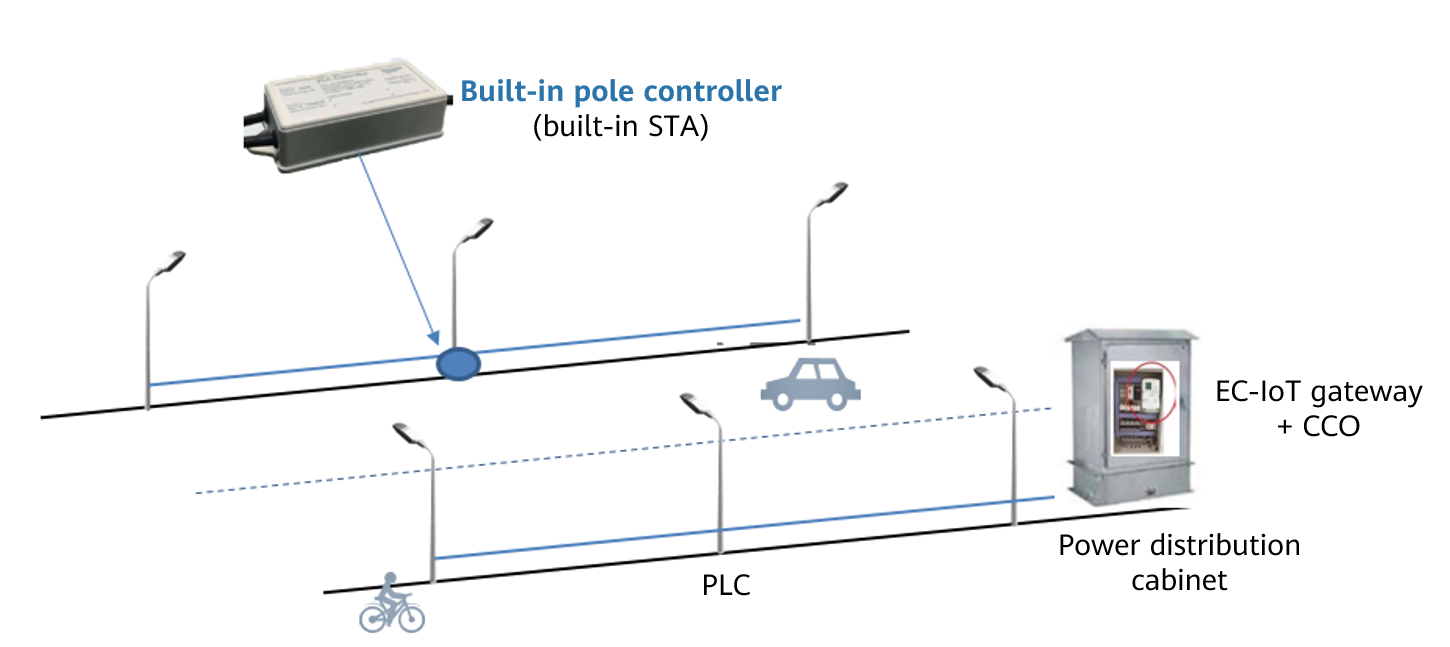

Smart Street Lamps

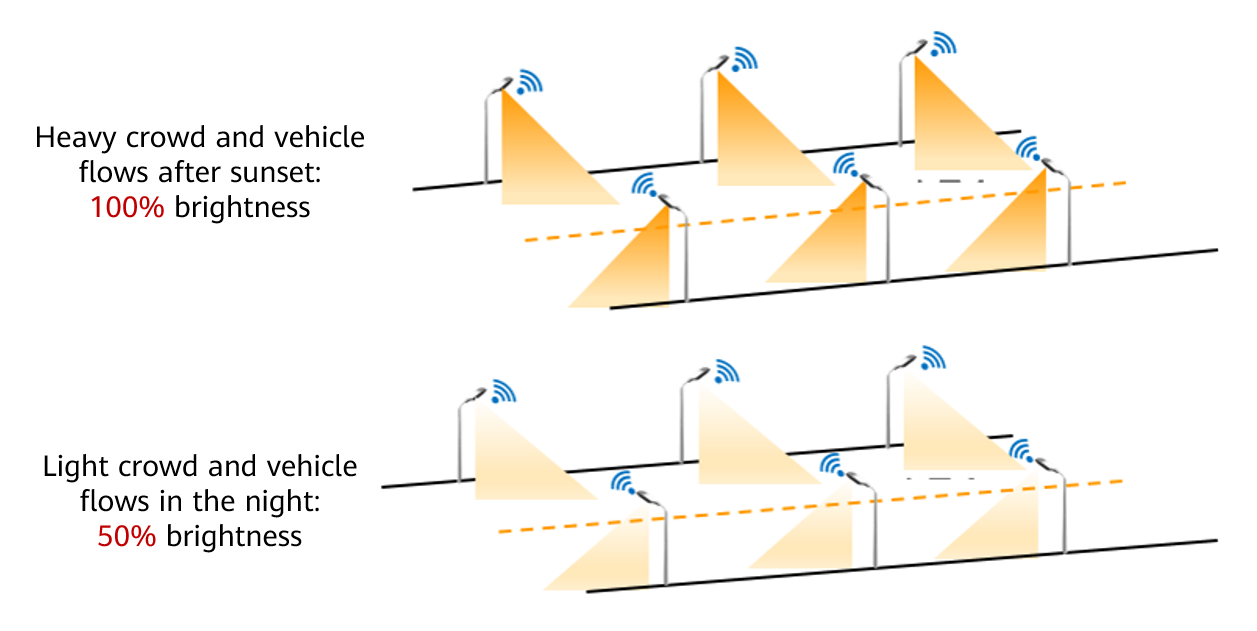

A smart city is characterized by an unprecedented level of intelligence, which drives traditional street lamps to transform toward intelligence. Smart lamp poles have become the best choice of IoT. With PLC-IoT and edge computing technologies, the smart street lamp solution intelligently adjusts the brightness of street lamps based on the time, surrounding environment, as well as longitude and latitude, reducing energy consumption.

PLC-IoT-powered street lamp control

Brightness adjustment based on time and longitude/latitude

- Author: Cui Yunlong

- Updated on: 2021-12-15

- Views: 17150

- Average rating: