What Is IIoT?

Leveraging IoT sensing and communication technologies, industrial IoT (IIoT) integrates various collection sensors, control sensors, and controllers with sensing and control capabilities into each phase of industrial production. This upgrades traditional industries to a new level of intelligence.

IIoT is primarily used in industries such as manufacturing, transportation, energy, and mining to optimize the production process, improve production efficiency, and reduce manufacturing costs.

- What Is IIoT?

- Why Do We Need It?

- What Are the Differences Between IIoT and IoT?

- What Are the Differences Between IIoT and Industrial Internet?

- What Are the Typical Characteristics of IIoT?

- IIoT Solution Architecture

- What Are the Key Technologies Used in IIoT?

- What Are the Typical Application Scenarios of IIoT?

What Is IIoT?

Leveraging IoT sensing and communication technologies, IIoT integrates various collection sensors, control sensors, and controllers with sensing and control capabilities into each phase of industrial production. This enhances production efficiency, improves product quality, and reduces product costs and resource consumption, thereby upgrading traditional industries to a new level of intelligence.

IIoT is the application of IoT in the industrial field, but it is not as simple as just "industry + IoT". IIoT is a system of intelligent technologies that empowers smart manufacturing. Through network interconnection, data interworking, and system interoperability of industrial resources, IIoT flexibly allocates production materials, executes production processes as needed, effectively optimizes production techniques, and quickly adapts production environments. As a result, resources can be efficiently used and a new service-driven industrial ecosystem can be built.

Why Do We Need It?

IIoT promotes industry transformation and upgrade

With the rapid development of IoT technologies, a series of national strategies, such as Made in China 2025 and Industry 4.0, have been proposed and implemented. Against this backdrop, IIoT has emerged as a major driving force for the intelligent transformation of industrial systems. As a key element of emerging industries, IIoT has also been used across all phases of the lifecycle, including design, production, management, and service. Transforming traditional industries with IIoT will undoubtedly increase the economic value added (EVA) of industries and help transform economic development from production-driven to innovation-driven.

IIoT meets industry application requirements

As enterprise digital transformation proceeds, enterprises start to use IIoT to solve service problems. For example, they use sensors, instruments, and meters to monitor the status of production equipment, raw materials, and personnel in real time, intelligently execute the manufacturing process, and improve production efficiency and product quality. Identification technologies, such as radio frequency identification (RFID), are used to realize intelligent warehousing that interworks with the production process. This improves the efficient allocation of raw production materials. In addition, devices can obtain data through sensing methods to offer predictive warning and remote maintenance services, thus improving device maintenance efficiency. IIoT is widely applied throughout various stages of industrial manufacturing, solving many difficulties like overcapacity and cost pressure.

IIoT facilitates smart manufacturing

The manufacturing industry is facing the strategic challenges of improving production efficiency, conserving energy and reducing emissions, and restructuring industries. IIoT will profoundly change enterprises' production, operations, and management models. Smart manufacturing is a new production mode based on the in-depth integration of next-generation information and communications technologies and advanced manufacturing technologies. It runs throughout all manufacturing activities, including design, production, management, and service, and provides functions such as self-sensing, self-learning, self-decision-making, self-execution, and self-adaptation. The deployment and implementation of IIoT provide a cornerstone for smart manufacturing. Smart manufacturing will combine with IIoT to properly allocate supply chain resources to improve production and service efficiency and innovate intelligent management models in the manufacturing industry.

What Are the Differences Between IIoT and IoT?

IoT connects all objects to the Internet through information sensors for information exchange, implementing intelligent identification and management.

IIoT connects industrial sensors and instruments through the Internet. IIoT collects and analyzes industrial application data to optimize production processes, improve production efficiency, and reduce manufacturing costs. Currently, IIoT is mainly used in fields, such as manufacturing, transportation, energy, and mining.

As a subset of IoT, IIoT aims to implement transformation and upgrade in the industrial manufacturing field and focuses on improving the security and efficiency of production sites.

What Are the Differences Between IIoT and Industrial Internet?

The industrial Internet includes an enterprise intranet and an enterprise extranet. The enterprise intranet interconnects industrial devices, information systems, service processes, and personnel to implement vertical interconnection from workshops to decision-making layers. The enterprise intranet typically includes the backbone layer, aggregation layer, and access layer. The enterprise extranet needs to implement horizontal interconnection between upstream and downstream enterprises. Therefore, the industrial Internet covers IIoT, but further extends to enterprise information systems, service processes, and personnel.

As a subset of the Industrial Internet, IIoT refers to the application of IoT in industries. It focuses closely on the interconnection and communication between things as well as the connection of terminals and devices at the access layer of industrial field networks.

What Are the Typical Characteristics of IIoT?

IIoT has six typical characteristics: intelligent sensing, ubiquitous connectivity, digital modeling, real-time analysis, precise control, and iterative optimization.

Intelligent sensing

Intelligent sensing is the foundation of IIoT. Based on massive amounts of data generated during industrial production, logistics, and sales, IIoT uses sensing methods such as sensors and RFID to obtain information from different areas of the industrial lifecycle, including personnel, machines, raw materials, process flows, and environments.

Ubiquitous connectivity

Ubiquitous connectivity is the prerequisite for IIoT. Industrial resources are connected to each other or the Internet through either wired or wireless connections to establish convenient and efficient IIoT information channels. This expands the scope and depth of connections between machines, between machines and people, and between machines and environments.

Digital modeling

Digital modeling is an approach to IIoT. Digital modeling maps industrial resources to the digital space and simulates the industrial production process in the virtual world. Supported by the powerful information processing capability of the digital space, digital modeling abstracts and models all elements of the industrial production process, thus providing effective decision-making regarding the operation of the IIoT physical industry chain.

Real-time analysis

Real-time analysis is a means of IIoT. Technical analysis methods are used to process sensed industrial resource data in real time in the digital space, establish an internal connection between the industrial resource status in the virtual space and the real space, and further visualize the abstract data to respond to external physical entities in real time.

Precise control

Precise control is the purpose of IIoT. Through processes such as status awareness, information interconnection, digital modeling, and real-time analysis of industrial resources, decisions based on virtual spaces are converted into control commands that can be understood by industrial resource entities and thus converted into actual operations, implementing precise information exchange and seamless collaboration between industrial resources.

Iterative optimization

Iterative optimization is the result of IIoT. The IIoT system can continuously learn and improve. By processing, analyzing, and storing industrial resource data, the system can form an effective and inheritable knowledge base, model library, and resource library. Raw materials, manufacturing processes, manufacturing techniques, and manufacturing environments of industrial resources are continuously improved to achieve the goal of optimal operations.

IIoT Solution Architecture

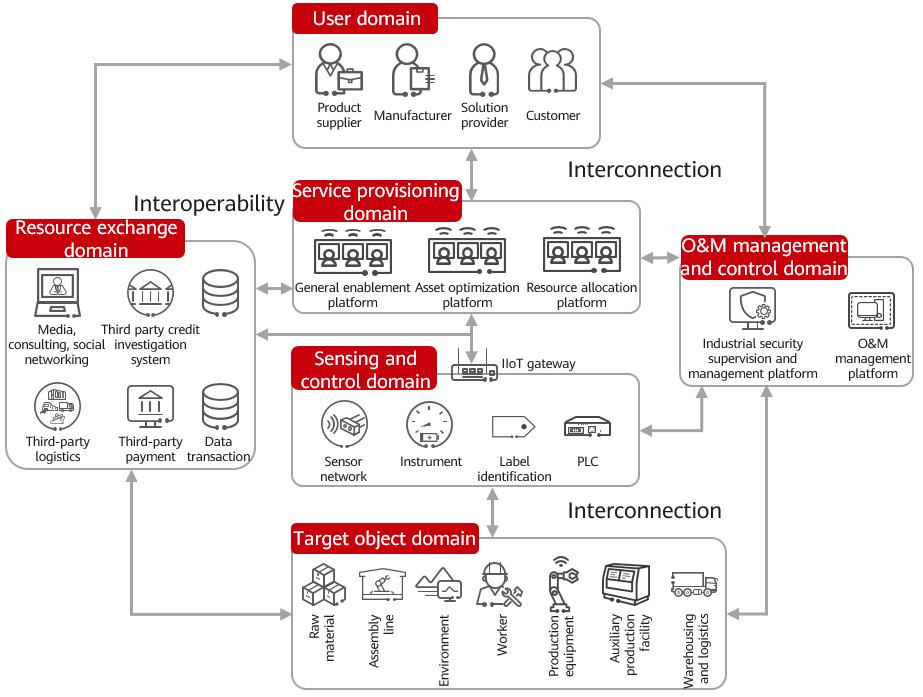

Based on the IoT conceptual model in GB/T 33474-2016 Internet of things—Reference architecture, the IIoT reference architecture consists of the target object domain, sensing and control domain, service provisioning domain, O&M management and control domain, resource exchange domain, and user domain.

IIoT reference architecture

Target object domain

Raw materials, raw product equipment, environments, and workers involved in industrial production are sensed, identified, and managed by sensors, instruments, meters, and labels in the sensing and control domain. In addition, information related to production, processing, transportation, circulation, and sales is obtained.

Sensing and control domain

The collected data is finally transmitted to the service provisioning domain through the IIoT gateway.

Service provisioning domain

The general enablement platform, asset optimization platform, and resource allocation platform provide services such as remote monitoring, energy management, and safe production.

O&M management and control domain

The industrial security supervision and management platform and O&M management platform ensure the stable, reliable, and secure running of other IIoT domains from two aspects: technical management of system operation, and compliance with laws and regulations.

Resource exchange domain

Information resources and market resources are exchanged and shared based on the application service requirements of the IIoT system and other related systems.

User domain

Users can access IIoT and the applicable IoT service port system. The user domain includes product suppliers, manufacturers, solution providers, customers, and governments.

What Are the Key Technologies Used in IIoT?

Key technologies involved in IIoT include sensing and control, network communications, information processing, and security management.

- Sensing and control technologies, which mainly include sensor, RFID, multimedia, and industrial control, are the core of IIoT deployment and implementation.

- Network communications technologies mainly include Ethernet and wireless communications technologies, which are the basis for IIoT interconnection and interworking.

- Information processing technologies include data cleaning, data analysis, data modeling, and data storage, which support IIoT applications.

- Security management technologies mainly include encryption, authentication, and intrusion prevention, which are key to IIoT deployment.

The following information details the highlights of Huawei's IIoT communications technologies.

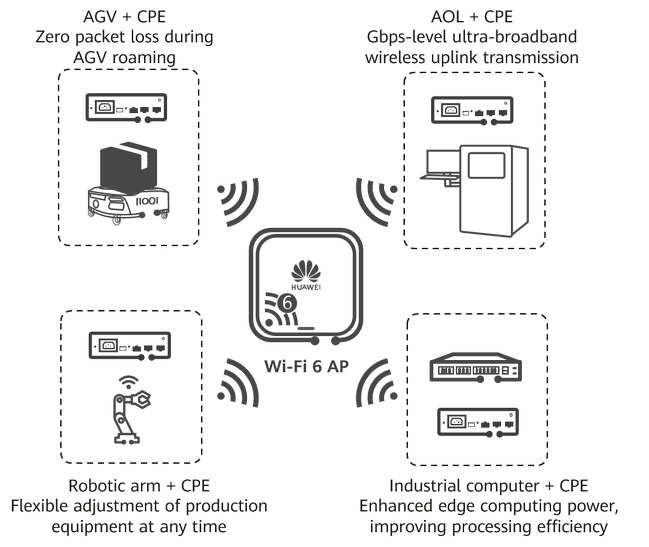

Wi-Fi 6 continuous networking

Wi-Fi technology is not restricted by wired connections. It facilitates fast access and mobile sharing of terminals and devices, and greatly reduces cabling costs. Wi-Fi has become the first choice for industrial terminals to access networks. However, traditional Wi-Fi networks often have coverage holes, resulting in poor network experience. Industrial scenarios have higher requirements on the bandwidth, latency, and reliability of Wi-Fi networks. For example, no packet loss is permitted during roaming of automated guided vehicles (AGVs) in production workshops; automation, real-time data collection, and cloud computing are required in the production process. To meet the network requirements of industrial production for high bandwidth, high reliability, and low latency, Huawei has launched AirEngine series Wi-Fi 6 products to realize full wireless IIoT connections. Wi-Fi 6 CPE converts wired signals into wireless signals, allowing outdated production devices to access new wireless networks.

Wi-Fi 6 network and Wi-Fi 6 CPEs in the manufacturing field

Wi-Fi & IoT converged access

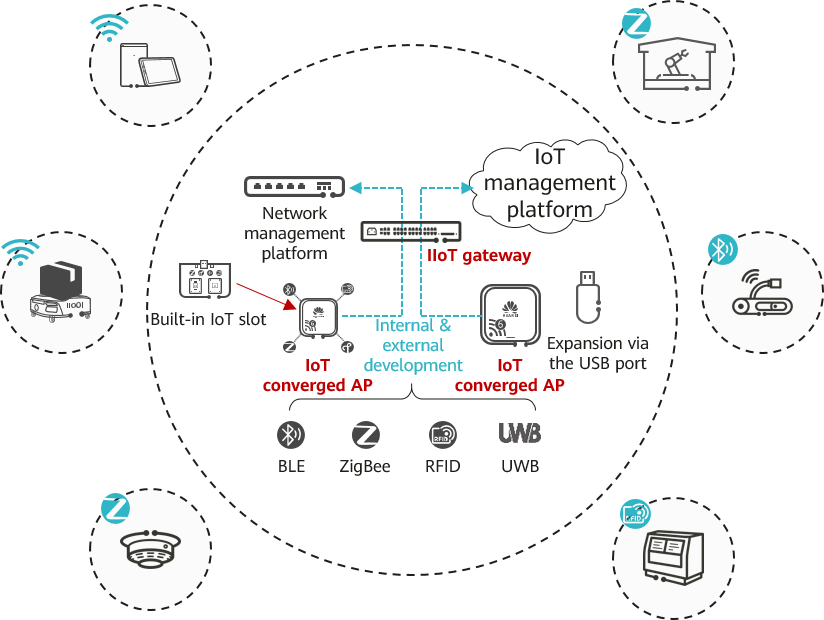

There are various access protocols for industrial terminals, such as Wi-Fi, Bluetooth, RFID, and ZigBee. Different types of IoT terminals can connect to IIoT through their respective IoT gateways. Huawei has launched Wi-Fi & IoT convergence technology. The Huawei IIoT gateway offers open software and hardware resources and supports IIoT protocols to implement IP-based connections.

Wi-Fi & IoT converged access

What Are the Typical Application Scenarios of IIoT?

Manufacturing industry: application of IIoT in automotive manufacturing enterprises

The automobile production process is complex, and the production of a vehicle involves over 100 departments, including stamping, welding, painting, and final assembly. The entire production process involves the cooperation of people (such as production personnel), machines (such as production equipment), and things (such as raw materials and cameras). As the foundation of digital infrastructure, networks play a vital role in the intelligent transformation of automobile enterprises, covering R&D, design, manufacturing, and service processes. IIoT fully connects people, machines, and things throughout all production processes of automobile enterprises, supports the intelligent transformation of the automobile industry, and achieves "data to the cloud, intelligence from the cloud".

Transportation industry: application of IIoT in production industrial control networks for ports

As comprehensive transportation hubs, ports are the distribution centers of industrial and agricultural products as well as imported and export materials. Bridge cranes are where the production business starts at ports. After entering a port, a ship undergoes processes such as cargo unloading with a bridge crane, container tallying, horizontal transportation in the yard, and loading and unloading in the yard according to the flow direction of cargoes. Workers are required to operate bridge cranes in driver's cabs at a height of nearly 50 meters. Long-time working at such heights often causes exhaustion and poses safety risks. Therefore, remote control and reconstruction of bridge cranes are an inevitable trend of smart port construction. IIoT plays an important role in promoting the automation and intelligent construction of operation equipment at ports, connecting cameras on bridge cranes, and uploading video data to the remote control platform.

Energy industry: application of IIoT in industrial networks for mining

Coal mines are vital mine resources. The coal mining industry faces challenges such as high risks, high labor intensity, and low output. Intelligent construction is an important trend of the coal mining industry. IoT technologies are being widely used in the intelligent construction of coal mines. Sensors and monitoring devices are used in coal mines to monitor and manage devices and personnel in real time. HD cameras are deployed underground. Video data is uploaded to the on-site remote control room through IIoT for remote monitoring and control on the fully mechanized face, monitoring of the operation sequence on the excavation face, and intelligent monitoring on main conveyor belts. This process enables personnel in the underground centralized control center and on-site operation and maintenance center to restore the operation sites on the fully mechanized face and excavation face, implementing routine intelligent inspection on belts, identification of the coal volume on belts, and recognition of foreign objects on belts. As such, continuous production can be ensured.

- Author: Chen Ying

- Updated on: 2023-11-13

- Views: 1956

- Average rating: